Industrial Gas Springs - Ace

We are Dealer / Distributor, Supplier of reputed Manufacturer Ace for Industrial Gas Springs, Hydraulic Dampers, Profile Dampers, Rotary Dampers. We are based in Pune, Maharashtra, India.

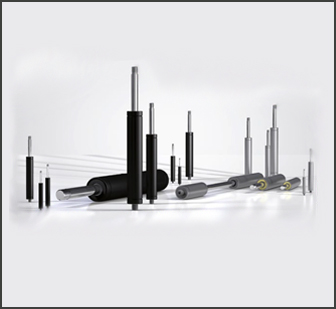

Anyone who wants to lift or lower loads with control and without excessive strength relies on the industrial gas push type springs from ACE. These maintenance free, ready-to-install machine elements, which are available from stock, support sheer muscle power and reliably open and hold.

Available with body diameters of 8 to 70 mm and forces from 10 to 13,000 N, ACE gas push type springs are characterised by a huge variety and maximum service life. The first is achieved thanks to the number of available connections and fittings for simple attachment and the latter with high quality design and materials. Whether they are made of steel or stainless steel, these components make any work easier and also make a particularly good impression visually in every branch.

Takes over when things get too tight for gas If ACE gas push type springs cannot be used due to a lack of space, ACE's industrial gas pull type springs come into their own. The compact assistants with body diameters of 15 to 40 mm are effective in the direction of traction and work in the opposite way to the principle of gas push type springs.

This means that the gas pressure in the cylinder draws the piston rod in and, when closing a fl ap for example, supports the manual force with the pressure springs. ACE's gas pull type springs are also self-contained, maintenance-free machine elements and equipped with a standard valve to individually regulate the gas pressure, whereby they cover forces between 30 and 5,000 N. Any installation position, extensive DIN standardised accessories and various models enable universal use.

Multi-talent in speed control

Hydraulic feed controls from ACE are recommended as the perfect solution e.g. when sawing, cutting, drilling and in order to prevent the stick-slip effect on pneumatic cylinders, amongst others. They can be precisely adjusted and provide speeds from 12 mm/min. with a very low feed force or up to 38 m/min. with a high feed rate.

The maintenance-free, ready-to-install hydraulic feed controls are self-contained, hydraulic elements regulated by a precision throttle. The feed rate is set from the outside by turning the setting adjuster. The tried-and-testing rolling diaphragms used in many ACE shock absorbers also serve as a dynamic sealing element for a hermetic seal as well as volume compensation for the piston rod and resetting element.

The low cost alternative for continuous duty

The exceedingly successful TUBUS series from ACE is a perfect alternative,when masses don't need to be decelerated to an exact point.Available in more than 140 different versions, the profi le dampers areused to slow down masses, particularly under extreme conditions.

They are also recommended for use if there is little installation space available. Manufactured in co-polyester elastomer, the highly resistant absorbers provide the best benefi ts in areas where other materials fail or where a similarly high service life of up to 1 million load changes cannot be achieved. They are affordable, compact and light and absorb the energy with different damping characteristics depending on the design.

Small dampers refi ne end product

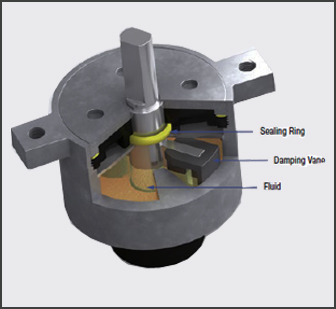

ACE rotary dampers mainly provide an invisible yet valuable service as a maintenance-free machine element to allow controlled deceleration of

rotary or linear movements.

They are often necessary to make careful opening and closing of small lids, compartments and drawers possible and they protect sensitive components while

increasing the quality and value of products. They are easy to integrate. The

harmoniously gentle movements of these little decelerators can be achieved with

continual rotation or with limited pivoting angles. They slow down left, right or

double sided rotation. Suitable for almost any application and currently also availa-

ble in adjustable variations, they provide braking torques of 0.05 Ncm to 40 Nm.

Request a Quote